ASCII example#

The model setup for this example is available in the following formats:

This example models the exact same model found in the basic example and runs the same optimization. However, in this script the model is defined in ASCII files and optimized by running a command file. pyshop provides methods for reading models from ASCII files and executing commands in command files. ASCII files have historically been the main method for defining Shop models, and command files have been used for executing commands on such ASCII models. In pyshop it is possible to combine the older approach with the newer python-based one.

Imports and settings#

The first thing we do is to import the needed packages. You can import whichever packages you like, however we use the following ones for this example:

Pandas for structuring our data into dataframes

pyshop in order to create a SHOP session

Plotly backend for dynamic graph plotting

import pandas as pd

from pyshop import ShopSession

pd.options.plotting.backend = "plotly"

Instancing SHOP#

In order to have SHOP receive our inputs, run the model we create and give us results, we need to declare a running SHOP session, in this example to the instance ‘shop’.

You may create multiple SHOP sessions simultaneously if needed.

# Creating a new SHOP session to the instance 'shop'

shop = ShopSession()

We might also want to check the current versions of SHOP and its solvers.

# Writing out the current version of SHOP

shop.shop_api.GetVersionString()

'17.10.1 Cplex 20.1.0 Gurobi 7.5 OSI/CBC 2.9 Armadillo 15.2.1 (Medium Roast Deluxe) Intel MKL 2023.0.0 2026 - 02 - 05'

Reading ASCII files as input data#

We make use of the read_ascii_file function to save data from file into the shop instance we created in the previous cell. Note that it is important to import files in the correct order, meaning you cannot import something that relies on data that you have not imported from before.

The example of importing files below show best practice by

First importing the data structure and indexing such as the time horizon and time period(s) of the model, and thus its data

Furthermore importing the model topology and parameters

Lastly populating the model with data and time series

Also note that the file(s) must be present in the same working directory/folder as the script/notebook that you are executing, if not using (absolute) paths.

Reading and verifying time units#

We start by importing the time period and time resolution from the file test_time.ascii.

# Importing the time period and time resolution

shop.read_ascii_file('ascii_time.ascii')

We then verify which time data has been read into the shop instance.

# Listing time resolution data from the model instance

shop.get_time_resolution()

{'starttime': Timestamp('2018-02-27 00:00:00'),

'endtime': Timestamp('2018-02-28 00:00:00'),

'timeunit': 'hour',

'timeresolution': 2018-02-27 1.0

Name: data, dtype: float64}

Reading and verifying the topology and parameters#

After the time structure has been correctly imported, we move on to importing the watercourse topology and its static parameters from the file test_model.ascii

# Importing the model's topology and assosiated parameters

shop.read_ascii_file('ascii_model.ascii')

We can then verify what has been read into the shop instance by quering data using different get functions.

List reservoirs and reservoir parameters in current model#

In order to retrieve the current reservoir names in the model on the current shop instance, we can use

# Listing the reservoirs in the current model

shop.model.reservoir.get_object_names()

['Reservoir1', 'Reservoir2']

Once we have verified the names, we can make use of them for more detailed queries, such as volume/head relations (stage-storage curves)

# Listing the volume/head relation in Reservoir1

shop.model.reservoir.Reservoir1.vol_head.get()

0.0 90.0

12.0 100.0

14.0 101.0

Name: 0.0, dtype: float64

# Listing the volume/head relation in Reservoir2

shop.model.reservoir.Reservoir2.vol_head.get()

0.0 40.0

5.0 50.0

6.0 51.0

Name: 0.0, dtype: float64

The flow descriptions

# Listing the overflow description in Reservoir1

shop.model.reservoir.Reservoir1.flow_descr.get()

100.0 0.0

101.0 1000.0

Name: 0.0, dtype: float64

Attributes like HRL and LRL, can just as easily be retrieved

# Listing the highest regulated level (HRL) in Reservoir1

shop.model.reservoir.Reservoir1.hrl.get()

100.0

# Listing the lowest regulated level (LRL) in Reservoir1

shop.model.reservoir.Reservoir1.lrl.get()

90.0

List plants and plant parameters in current model#

The same process is applicable for all other object types, such as plants. We can retrieve the current plant names

# Listing the plants in the current model

shop.model.plant.get_object_names()

['Plant1', 'Plant2']

And then verify what has been read into the model by querying attributes from the objects using the get functions

# Listing the number of generators on Plant1

shop.model.plant.Plant1.num_gen.get()

1

# Listing the penstock loss on Plant1

shop.model.plant.Plant1.penstock_loss.get()

[0.0001]

List generators and generator parameters in current model#

And again, if we want to verify the generators and its parameters, we can do use the same approach as above

# Listing the generators in the current model

shop.model.generator.get_object_names()

['Plant1_G1', 'Plant2_G1']

# Listing the number of generators on Plant1

shop.model.generator.Plant1_G1.turb_eff_curves.get()

[25.0 80.0

90.0 95.0

100.0 90.0

Name: 90.0, dtype: float64,

25.0 82.0

90.0 98.0

100.0 92.0

Name: 100.0, dtype: float64]

Since the ascii file also included the connections between reservoirs, plants and generators, we can then verify if the topology is correctly set up, by graphing out the topology tree.

# Print out the topology

dot = shop.model.build_connection_tree()

display(dot)

Reading and verifying the input data#

After the topology and model structure has been set up correctly, we can populate additional data needed for SHOP to run, such as initial reservoir levels, endpoint descriptions (water values), market(s), inflow and other time dependent data, i.e. time series

# Importing other input data to the model

shop.read_ascii_file('ascii_data.ascii')

List initial input data and time series#

We can retrieve the newly imported static data out for inspection like before;

# Retrieve the start volume of Reservoir1

shop.model.reservoir.Reservoir1.start_vol.get()

0.0

# Retrieve the endpoint description (water value) of Reservoir1

shop.model.reservoir.Reservoir1.energy_value_input.get()

39.7

But now we are also introduced to time dependent data in time series

# Retrieve the inflow to Reservoir1

shop.model.reservoir.Reservoir1.inflow.get()

2018-02-27 00:00:00 101.0

2018-02-27 01:00:00 50.0

2018-02-27 02:00:00 50.0

2018-02-27 03:00:00 50.0

2018-02-27 04:00:00 50.0

2018-02-27 05:00:00 50.0

2018-02-27 06:00:00 50.0

2018-02-27 07:00:00 50.0

2018-02-27 08:00:00 50.0

2018-02-27 09:00:00 50.0

2018-02-27 10:00:00 50.0

2018-02-27 11:00:00 50.0

2018-02-27 12:00:00 50.0

2018-02-27 13:00:00 50.0

2018-02-27 14:00:00 50.0

2018-02-27 15:00:00 50.0

2018-02-27 16:00:00 50.0

2018-02-27 17:00:00 50.0

2018-02-27 18:00:00 50.0

2018-02-27 19:00:00 50.0

2018-02-27 20:00:00 50.0

2018-02-27 21:00:00 50.0

2018-02-27 22:00:00 50.0

2018-02-27 23:00:00 50.0

Name: inflow, dtype: float64

Which in many cases also can be useful to plot

# Plotting the inflow to Reservoir 1

shop.model.reservoir.Reservoir1.inflow.get().plot(title="Inflow to Reservoir 1", labels=dict(index="time", value="m3/s", variable=""))

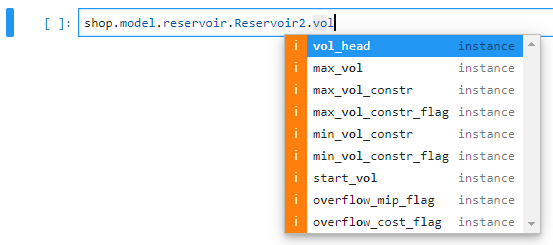

For a complete overview of all objects and attributes you can query data from, see the SHOP reference manual’s attribute section, or use a Language Server Protocol (LSP) in your IDE (which is included in the Lab) as illustrated below for an even easier and dynamic workflow.

Running SHOP optimizations and commands from file#

Once the model is fully imported and verified, we can then call for the optimizer. Since we now control all commands from a separate command file, this file needs to be inspected (and optinally altered and saved) before running the file in pyshop by using the run_command_file command.

# Running the command file and executing SHOP based on the imported input

shop.run_command_file('.', 'ascii_commands.txt')

In this example, we chose CPLEX as the solver, enabled universal MIP and ran three full and three incremental iterations before we wrote the results to files.

For a full overview of the possible commands you can use when running SHOP, see the SHOP reference manual’s command section.

Plotting the results#

Finally, we can review the result from SHOP by plotting the graphs we want.

# Defining a plot dataframe to combine multiple time series in the same dataframe for plotting purposes (NB: they need to have the same time index)

plot = pd.DataFrame()

# Retrieving the reservoir trajectories adding them to the plot dataframe

plot["Reservoir1"]=shop.model.reservoir.Reservoir1.storage.get()

plot["Reservoir2"]=shop.model.reservoir.Reservoir2.storage.get()

# Plotting the figure

plot.plot(title="Reservoir trajectories", labels=dict(index="Time", value="Mm3", variable=""))

Files#

ascii_model.ascii#

RESERVOIR attributes Reservoir1

#ID;Water_course;Type;Maxvol;Lrl;Hrl;

10000 0 0 12.00000 90.00000 100.00000

RESERVOIR vol_head Reservoir1

#Id;Number;Reference;Pts;X_unit;Y_unit

10000 0 0.000 9 MM3 METER

# x_value; y_value;

0.00000 90.00000

12.00000 100.00000

14.00000 101.00000

RESERVOIR flow_descr Reservoir1

#Id;Number;Reference;Pts;X_unit;Y_unit

10000 0 0.000 2 METER M3/S

# x_value; y_value;

100.00000 0.000

101.00000 1000.000

PLANT attributes Plant1

#Id;Water_course;Type;Bid_area;Prod_area;Num_units;Num_pumps;

10500 0 0 1 1 1 0

#Num_main_seg;Num_penstock;Time_delay;Prod_factor;Outlet_line;

1 1 0 0.000 40.000

#Main tunnell loss

0.0002

#penstock loss

0.0001

GENERATOR attributes Plant1 1

#Id Type Penstock Nom_prod Min_prod Max_prod Start_cost

10600 0 1 100.0 25.0 100.0 500.000

GENERATOR gen_eff_curve Plant1 1

#Id;Number;Reference;Pts;X_unit;Y_unit

10600 0 0.000 2 MW %

# x_value; y_value;

0.0 95.0

100.0 98.0

GENERATOR turb_eff_curves Plant1 1

#Id;Number;Reference;Pts;X_unit;Y_unit

10600 0 90.000 3 M3/S %

# x_value; y_value;

25.0 80.0

90.0 95.0

100.0 90.0

GENERATOR turb_eff_curves Plant1 1

#Id;Number;Reference;Pts;X_unit;Y_unit

10600 0 100.000 3 M3/S %

# x_value; y_value;

25.0 82.0

90.0 98.0

100.0 92.0

RESERVOIR attributes Reservoir2

#ID;Water_course;Type;Maxvol;Lrl;Hrl;

10000 0 0 5.00000 40.00000 50.00000

RESERVOIR vol_head Reservoir2

#Id;Number;Reference;Pts;X_unit;Y_unit

10000 0 0.000 9 MM3 METER

# x_value; y_value;

0.00000 40.00000

5.00000 50.00000

6.00000 51.00000

RESERVOIR flow_descr Reservoir2

#Id;Number;Reference;Pts;X_unit;Y_unit

10000 0 0.000 2 METER M3/S

# x_value; y_value;

50.00000 0.000

51.00000 1000.000

PLANT attributes Plant2

#Id;Water_course;Type;Bid_area;Prod_area;Num_units;Num_pumps;

10500 0 0 1 1 1 0

#Num_main_seg;Num_penstock;Time_delay;Prod_factor;Outlet_line;

1 1 0 0.000 0.000

#Main tunnell loss

0.0002

#penstock loss

0.0001

GENERATOR attributes Plant2 1

#Id Type Penstock Nom_prod Min_prod Max_prod Start_cost

10600 0 1 100.0 25.0 100.0 500.000

GENERATOR gen_eff_curve Plant2 1

#Id;Number;Reference;Pts;X_unit;Y_unit

10600 0 0.000 2 MW %

# x_value; y_value;

0.0 95.0

100.0 98.0

GENERATOR turb_eff_curves Plant2 1

#Id;Number;Reference;Pts;X_unit;Y_unit

10600 0 90.000 3 M3/S %

# x_value; y_value;

25.0 80.0

90.0 95.0

100.0 90.0

GENERATOR turb_eff_curves Plant2 1

#Id;Number;Reference;Pts;X_unit;Y_unit

10600 0 100.000 3 M3/S %

# x_value; y_value;

25.0 82.0

90.0 98.0

100.0 92.0

# From_type/To_type From_name To_name

CONNECT RESERVOIR/PLANT Reservoir1 Plant1

CONNECT PLANT/RESERVOIR Plant1 Reservoir2

CONNECT RESERVOIR/PLANT Reservoir2 Plant2

ascii_data.ascii#

STARTRES 2 METER

# Name Start reservoir(meters above sea level)

Reservoir1 92

Reservoir2 43

RESERVOIR inflow Reservoir1

# Id number starttime time_unit period data_type y_unit npts

0 0 2018022700 HOUR 8760 -1 M3/S 1

# time y

2018022700 101

2018022701 50

RESERVOIR inflow Reservoir2

# Id number starttime time_unit period data_type y_unit npts

0 0 2018022700 HOUR 8760 -1 M3/S 1

# time y

2018022700 0

RESERVOIR endpoint_desc Reservoir1

# Number Ref Npkt x_unit y_unit

0 1 0 1 Mm3 Kroner

0 39.7

RESERVOIR endpoint_desc Reservoir2

# Number Ref Npkt x_unit y_unit

0 1 0 1 Mm3 Kroner

0 38.6

MULTI_MARKET price_buy 1

# Id number starttime time_unit period data_type y_unit npts

0 0 2018022700 HOUR 8760 -1 M3/S 1

# time y

2018022700 40.01

MULTI_MARKET price_sale 1

# Id number starttime time_unit period data_type y_unit npts

0 0 2018022700 HOUR 8760 -1 M3/S 1

# time y

2018022700 39.99

MULTI_MARKET max_buy 1

# Id number starttime time_unit period data_type y_unit npts

0 0 2018022700 HOUR 8760 -1 M3/S 1

# time y

2018022700 9999

MULTI_MARKET max_sale 1

# Id number starttime time_unit period data_type y_unit npts

0 0 2018022700 HOUR 8760 -1 M3/S 1

# time y

2018022700 9999

ascii_time.ascii#

OPTIMIZATION time

#Start_time; End_time;

20180227 20180228

# N_full_iterations Accuracy;

OPTIMIZATION 100 -1

#Id Number Start_Time Time_unit Period Data_type Y_unit Pts

0 0 20180227 HOUR 525600 0 HOUR 1

# Time Time_resolution

2018022700 1.000

ascii_commands.txt#

set solver /cplex

set universal_mip /on

start sim 3

set code /inc

start sim 3

return simres res.txt

return simres /gen res_gen.txt